Inverter controller cooling

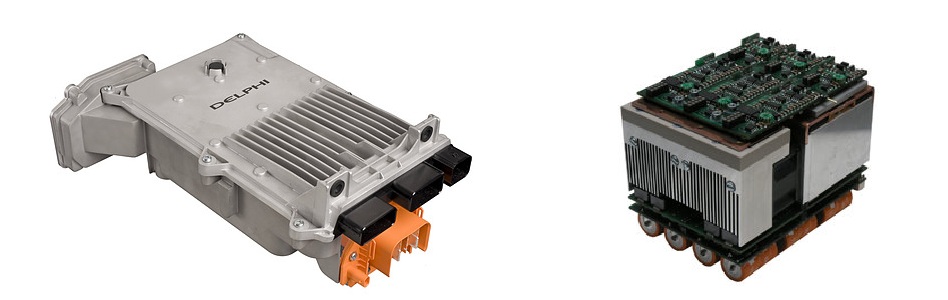

The customer

- Medium enterprise

- Sector: Electric equipment manufacturing

- Country: United Kingdom

The project

- Size: 65-70 man-hours

- Duration: 2-3 weeks

The problem

- Unknown cooling capacity and thermal resistance

- High controller temperature may lead to failure

- Natural convection deemed not enough

Proposed solution

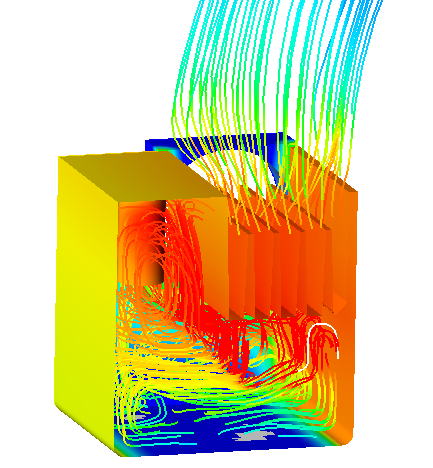

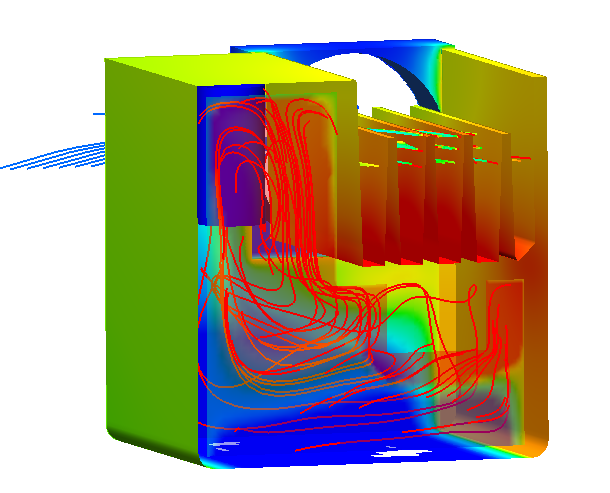

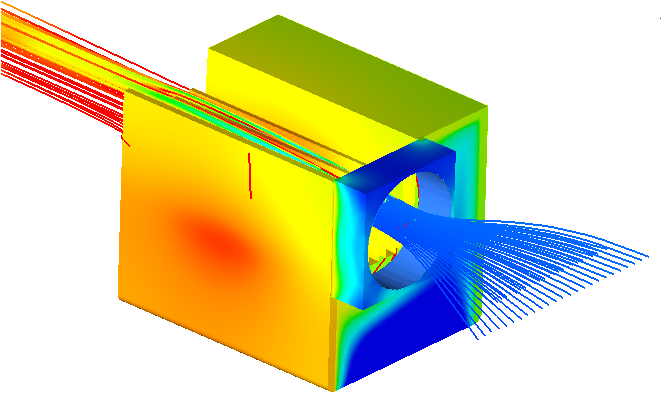

- Model natural and forced convections together with radiation

- Evaluate different fins and heat sink geometries

The simulations

- Thermal simulation for natural convection (CFD analysis)

- Thermal simulation for different forced convection conditions (CFD analysis)

- Thermal simulation for different heat sink geometries (CFD analysis)

Project overall results

- Required cooling power obtained. Heat sink optimal geometry and fan requirements learned.

- Savings over £31,000 for the customer in prototyping and testing (estimate).

- Savings of more than 8 weeks in development time (estimate).