Processing

Offshore production facilities on most oil and gas field developments face increasingly challenging conditions. With higher oil prices, unconventional sources such as very heavy crudes, oil sands, oil shale and methane hydrates are becoming more attractive. This wider spectrum of hydrocarbon sources introduces a new era in oil and gas treatment and separation.

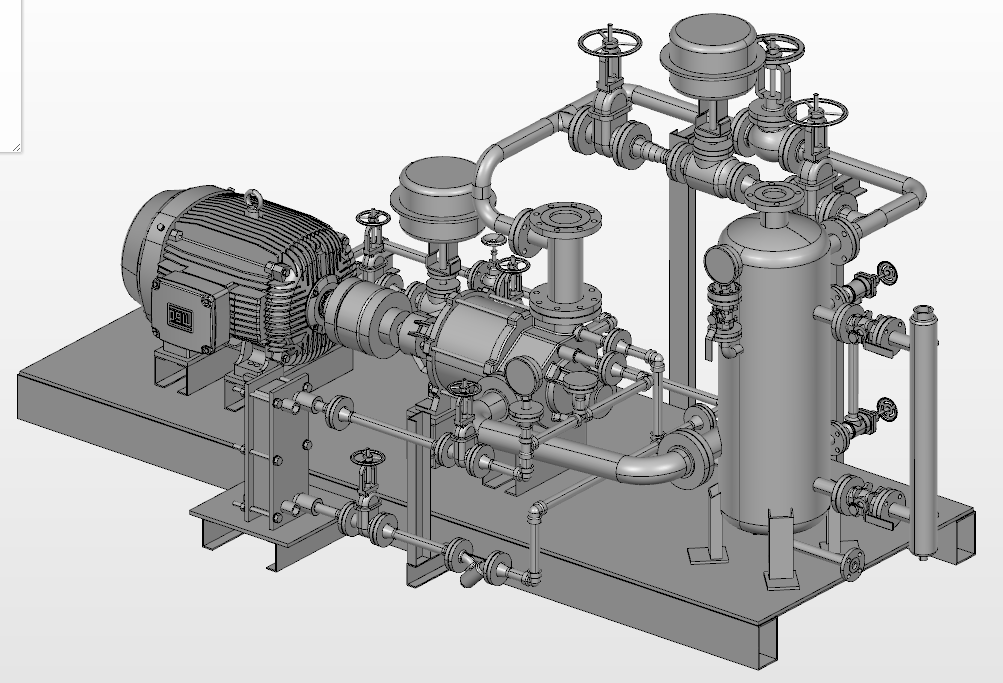

The full process is often designed for the specific requirements of the operator and requires an experienced process engineer to dimension it according to the expected product composition. CFD and FEA technologies can help process designers in this endeavour. Thermal and fluid dynamics studies will help determining the process efficiency of various designs and hence affect the equipment dimensioning. Stress, vibration and fatigue analyses will help assess the likelihood of failures during operation. Corrosion and erosion on the various sections of the system can also be modelled aiding the maintenance scheduling during operation or the extension of plant life through design modifications and retrofitting.

Oil processing

Offshore oil processing and separation analysis services. Fluid dynamics and mechanical studies.

Gas processing

Gas processing line optimisation using simulation. Gas dehydration and compression optimisation.

Water treatment

Analysis and optimisation of water treatment units on offshore facilities. FEA and CFD modelling services.

Other areas of oil and gas

Subsea

- S.U.R.F. and manifolds: Subsea Umbilicals, Risers and Flowlines (SURF) design and optimisation services using simulation technologies

- Subsea processing: Subsea and downhole separation, reinjection and boosting evaluation services using CFD and FEA

- Drilling & Completion: Offshore exploration, drilling, completion and decommissioning assessment services

Rig & Platform

- Structures: Production and processing offshore rig structures, mechanical and thermal-mechanical simulations

- Stability & Mooring: Offshore rigs and platforms stability and mooring calculation services

- Safety: Oil and gas safety and risk assessment services. Venting, flare and explosion studies