Nose landing gear

The customer

- Size: Large enterprise

- Sector: Aircraft manufacturing

- Country: France

The Project

- Size: 75-90 man-hours

- Duration: 4-5 weeks

The Problem

- Plastic deformations on some mechanism elements

- Early malfunction of the mechanism

Proposed solution

- Evaluate static stress under different cargo loads

- Assessment of maximum stress under landing conditions

The simulations

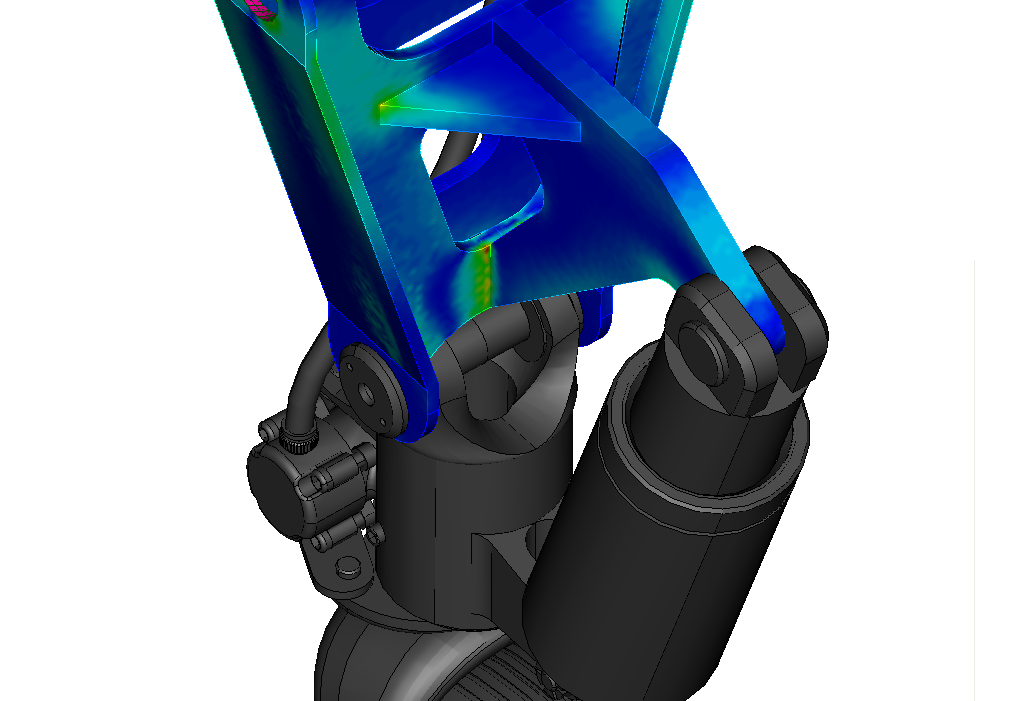

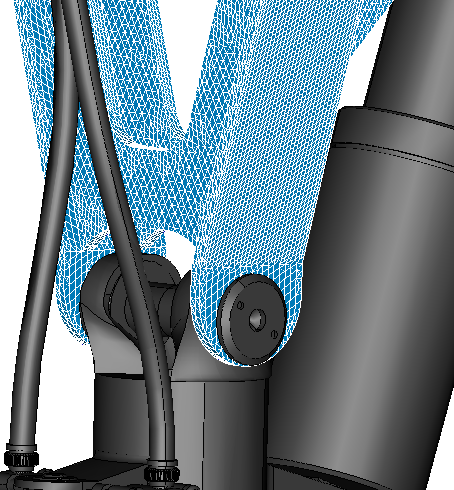

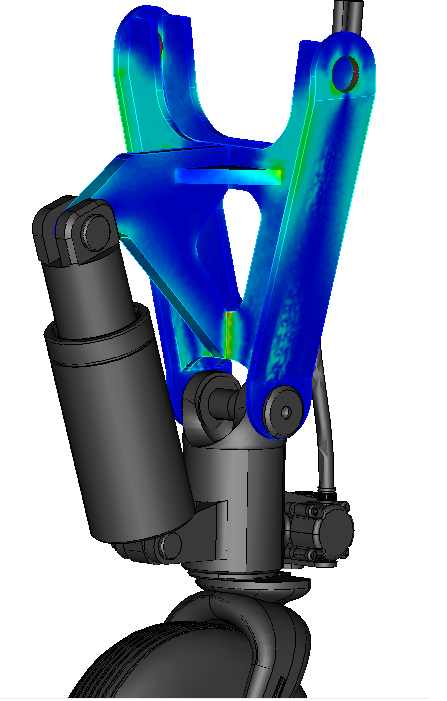

- Static stress analysis to find mechanical hotspots of the structure (FEA analysis)

- Dynamic impact analysis for landing conditions at maximum aircraft load (FEA analysis)

Project overall results

- Potential failure spots were located and re-design was adviced.

- Savings over £38,000 for the customer in prototyping and testing (estimate).

- Savings of more than 4 weeks in development time (estimate).