Plate heat exchanger

The customer

- Size: Medium-large company

- Sector: LNG operator

- Country: Germany

The Project

- Size: 80-100 man-hours

- Duration: 2-3 weeks

The Problem

- Poor flow distribution within the channels

- Chevron and channel geometry required optimisation

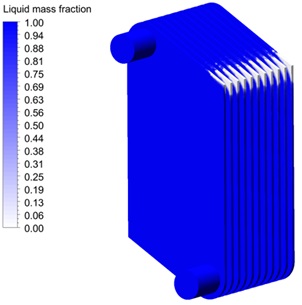

- Potential ice generation between the plates

Proposed solution

- Model the fluid flow for co-current and counter-current operation

- Phase change modelling for sub-zero energy carrying fluids

The simulations

- Steady-state CFD thermal simulation for the different flow scenarions (CFD analysis)

- Phase change study to obtain the areas where ice is prone to appear (CFD analysis)

Project overall results

- Optimised plates geometry for minimised stagnant zones and ice formation.

- Savings over £16,000 for the customer in prototyping and testing (estimate).

- Savings of more than 12 weeks in development time (estimate).