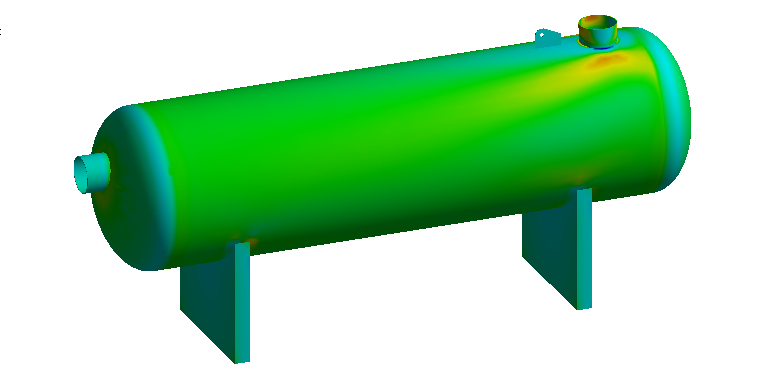

Pressure vessel

The customer

- Size: Medium-large enterprise

- Sector: Oil and gas

- Country: United Kingdom

The project

- Size: 45-60 man-hours

- Duration: 2-3 weeks

The problem

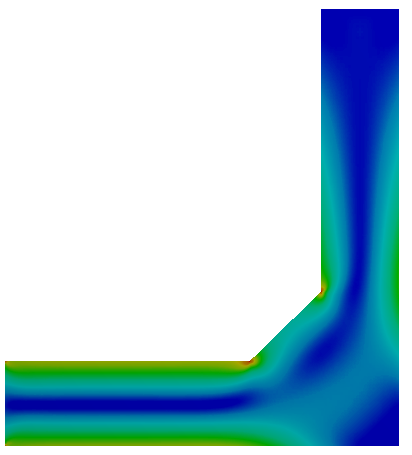

- Fatigue issues on some areas and weldings

- Early failure of the vessel in certain applications

- Maximum pressure capacity unknown

Proposed solution

- Stress analysis under different scenarios of pressure and loads for ASME VIII-2, BS-5500, EN-13445 and DNV-RP-C203

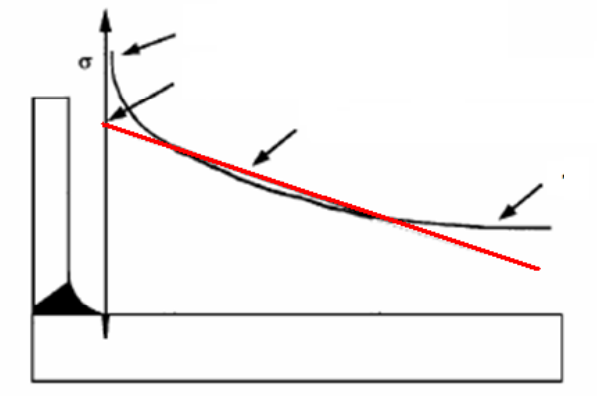

- Fatigue analysis simulation to estimate structure useful life (MTBF)

The simulations

- Stress analysis to find mechanical hotspots of the structure (FEA analysis)

- Fatigue simulations according to expected structure stress map (FEA analysis)

- Optimization of the design for extended product life (FEA analysis)

Project overall results

- Increase in structure useful life of 20%, maximum pressure capacity was learned from the different cases.

- Savings over £34,000 for the customer in prototyping and testing (estimate).

- Savings of more than 7 weeks in development time (estimate).

For more details about stress and fatigue calculations, please read our stress and fatigue on oil and gas sector white paper.