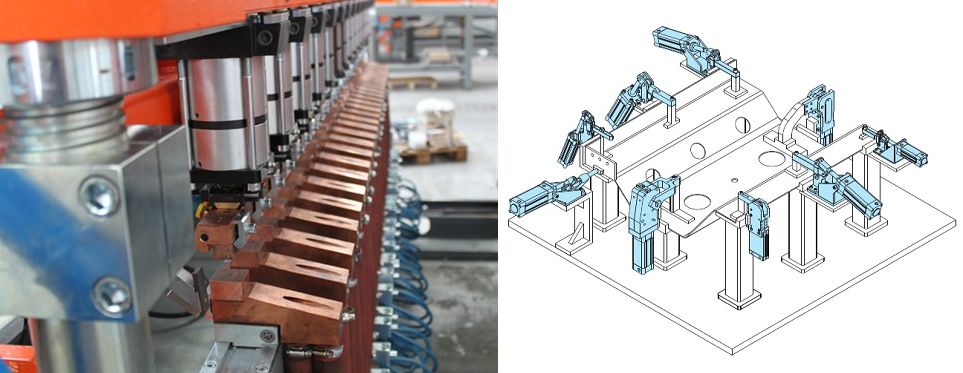

Pneumatic hold-down clamp

The customer

- Size: Small-medium enterprise

- Sector: Manufacturing equipment & supports

- Country: United Kingdom

The Project

- Size: 45-60 man-hours

- Duration: 2-3 weeks

The Problem

- Fatigue issues on some mechanism elements

- Early malfunction of the mechanism

- Maximum retention force capacity unknown

Proposed solution

- Stress analysis under different scenarios of force and position (angle)

- Fatigue analysis simulation to estimate structure useful life (MTBF)

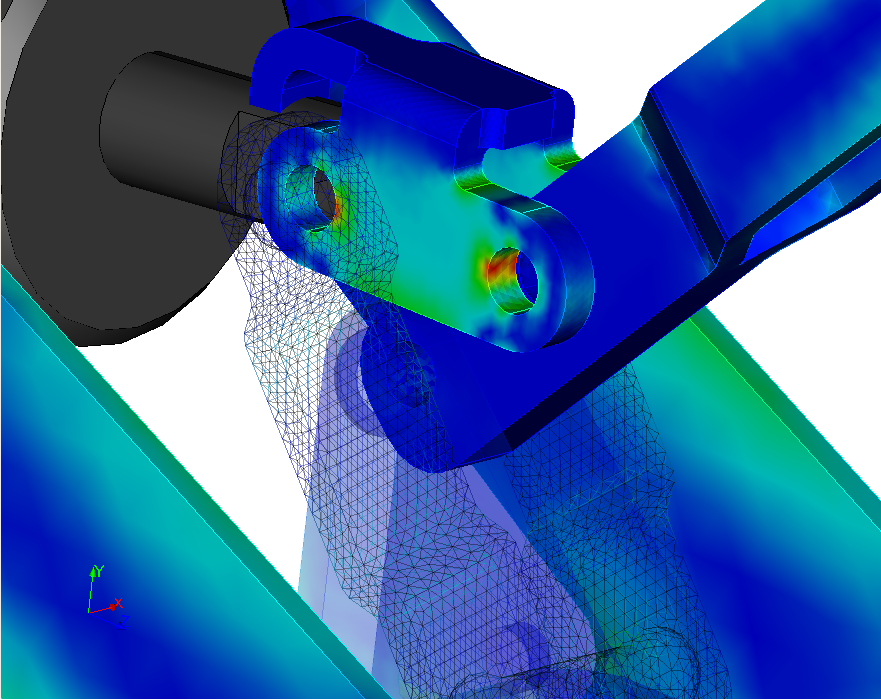

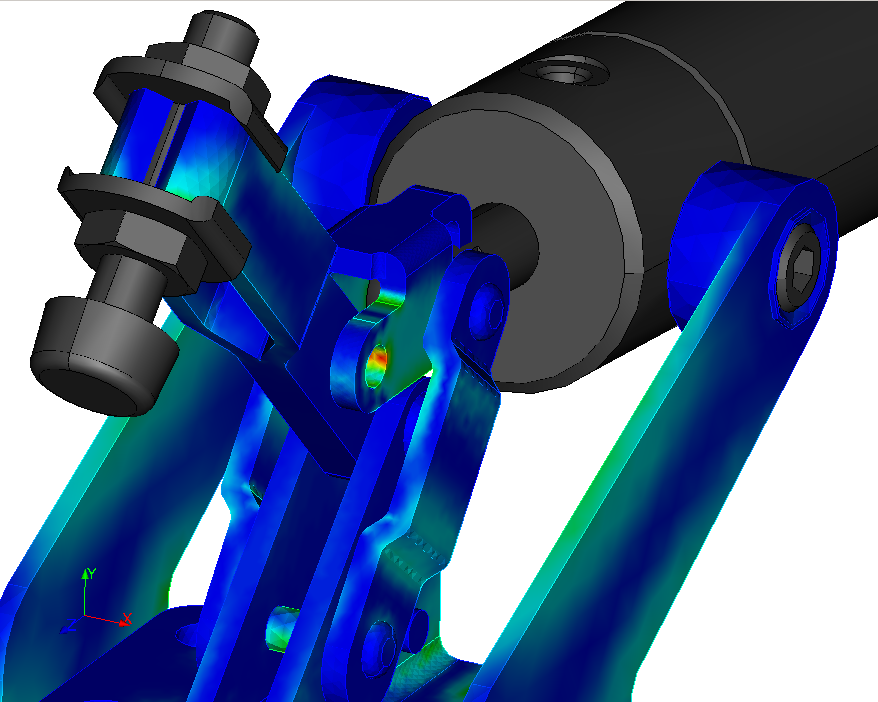

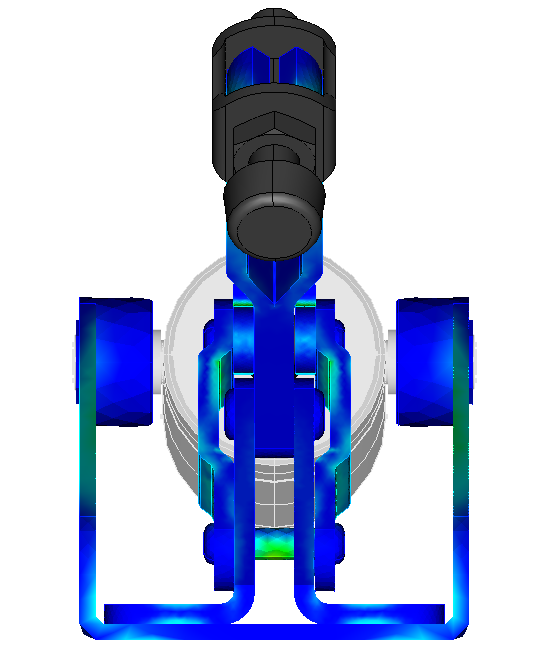

The simulations

- Stress analysis to find mechanical hotspots of the structure (FEA analysis)

- Fatigue simulations according to expected structure stress map (FEA analysis)

- Optimization of the design for extended product life (FEA analysis)

Project overal results

- Increase in structure useful life of 25%, maximum clamp forces were learned for the different cases.

- Savings over £14,000 for the customer in prototyping and testing (estimate).

- Savings of more than 6 weeks in development time (estimate).