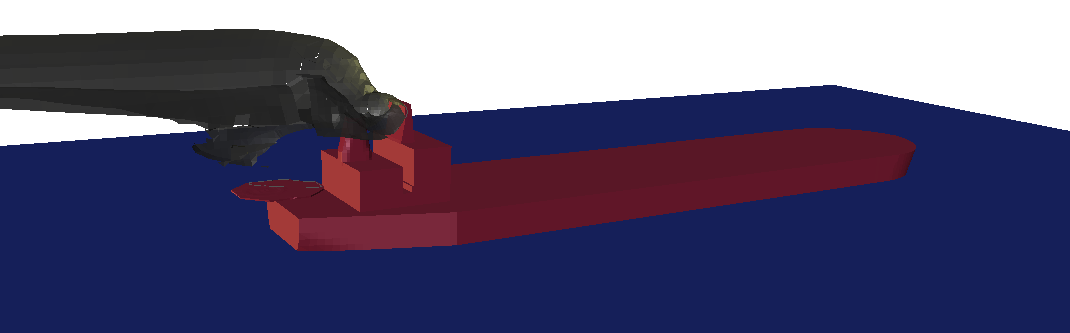

Tanker exhaust study

The customer

- Size: Large enterprise

- Sector: Oil and gas

- Country: United Kingdom

The project

- Size: 65-70 man-hours

- Duration: 2-3 weeks

The problem

- Helipad operation problems on certain wind conditions

- Ventilation issues in the back of the cabin

Proposed solution

- Different wind speed and tanker speed studies for different exhaust flow rates

- Visibility prediction on the helipad

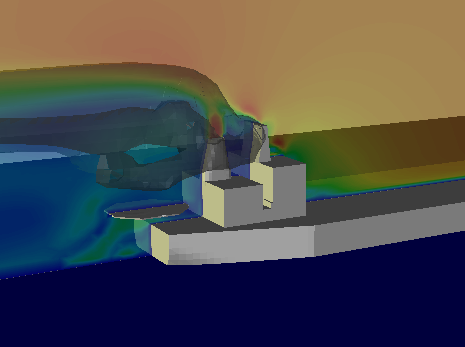

The simulations

- Flow analysis to determine smoke streams (CFD analysis)

- Diffusion CFD analysis of smoke under different wind conditions (CFD analysis)

- Optimization of the design for improved ventilation and helipad operation (CFD analysis)

Project overall results

- Reduced sensibility of the exhaust system to wind conditions. Safer helipad operation and ventilation of the cabin.

- Savings over £43,000 for the customer in prototyping and testing (estimate).

- Savings of more than 11 weeks in development time (estimate).