Taking advantage of PRE's CFD capabilities

Monday, March 24, 2014

Maintaining competitive advantage in product manufacturing has become more challenging than ever. The pace of technology advancements, increasing regulatory compliance requirements, and employee mobility are taking their toll on product design and manufacturers’ profitability. Consumer expectations forever increasing product performance at lower prices compound the problem

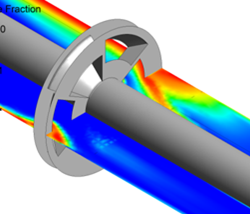

One overlooked area of design suitable for use as a competitive differentiator is computational fluid dynamics (CFD). At one time, CFD was only in the purview of the aerospace industry. But, with costs coming down due to improved software, most industries can benefit from the insight produced by CFD analysis. Any design that incorporates fluid flow or heat transfer is a candidate. Core applications include aerodynamics, building ventilation, data centers, electronics, filtration, flow control, heat exchangers, heating/refrigeration, lighting, and mixing.

Until about five or six years ago, almost everyone used a combination of rule of thumb and physical testing for prototyping. In the absence of any other way to model how fluid flows in and around products, engineers would use mathematical rules of thumb. With this “technique,” products were generally over-designed, since engineers wanted to make sure the products would pass compliance tests.

Over-design leads to poor materials use and eliminates margin optimization based on reducing materials costs. Because product design is part art and part science, rules of thumb can result in less innovative designs. A competitor using a more accurate modeling method could gain an advantage combining superior performance with improved aesthetics.

Rules of thumb applied, engineers then produce physical prototypes for testing. Problems with physical testing include lead-times for key components, which slow down prototyping, resulting in longer design phases, eventually pushing out the time to manufacture and entry to the market. Because designers are working with real parts in real time, costs can mount. Creating a prototype and taking it from an internal testing lab to a compliance testing lab, only to find that it doesn’t pass compliance specifications, can be a costly iterative cycle, considering the testing charges.

Today, there’s another way to model fluid flows, namely CFD, which leverages computing power to design and test more precise mathematical models. It provides a means to test different approaches without physical prototyping, allowing designers to explore iteratively design options working in the virtual world. While the underlying model is math-based, CFD software generates sophisticated visuals that make it easy to spot problems and modify variables for different outcomes.

Many manufacturers don’t have in-house CFD capabilities because it’s not a core competency and no one internally really knows the software well enough to make it work. Outsourcing to a CFD professional can provide in-house design teams with the expertise they lack. A CFD consultant can work collaboratively with any design team to improve fluid flows. The key is collaboration, because simulations can model an excellent flow system. But perhaps they are outside the design aesthetic, use the wrong material, or violate other specs like weight or size.

If a manufacturer can articulate its constraints up front, a CFD consultant can come up with options that meet the technical requirements and exceed design and material cost expectations. Simulation specialists have years of experience extracting design insight from diverse applications to imagine more creative solutions that address even the most challenging form factors and performance goals. Working collaboratively with a manufacturer, a CFD consultant can model several different designs and end up changing the design to improve fluid flows significantly.

Time to market is everything in the manufacturing business. Introducing new products with key performance advantages brings new revenues, and if you can do that faster than competitors, you gain the upper hand.