Rig and platform structures

A whole range of different structures are used offshore, depending on field size and water depth. In the last few years we have seen a gradual migration from mostly topside installations to increased sea bottom installations. However there is still a high percentage of oil field developments that require topside rigs and structures for either drilling, production, processing or offloading to tankers.

Ensuring rig's stability

Designing a production and processing floating structure is a very challenging engineering task that encompasses a wide variety of engineering disciplines, ranging from buoyancy and mooring studies to skid and modules fixation and structural integrity. Mechanical engineers rely on modern computing tools to aid the design process. Finite element analysis (FEA) is the most extended computational tool for stress, vibration and fatigue calculations of offshore structural components.

Semisubmersible and floating platforms rely on complex ballast systems and mooring configurations to prevent excessive movement ensuring a proper processing performance while keeping the mechanical integrity of the structure. FEA linear and non-linear analyses have been regularly applied over the last 10 years to assess this equilibrium of forces, especially on mooring lines, tendons and their connections to the floating structure. Linear elastic stress calculations under maximum operating and test conditions are often performed for those areas of the structure and joints where stress values are expected to be higher. In some instances though, these calculations are complemented with non-linear plastic FEA models in order to accurately obtain expected deformations on both the structure and the bolted/welded connection.

Mechanical assessment is certainly required on every offshore structure and the mooring systems that keep it in place. However, structural integrity studies do not end there. On a local level, frames and modules, skids and pipeline stack structures also require detailed stress analysis. Sea fastening assessments for all transported offshore equipment is also often carried out using finite element analysis.

Offshore structures, often fixed to one another and ultimately to the rig floating structure, are subject to numerous loads, both steady and oscillating. These include: self- and payload-weight, equipment vibration forces, thermal expansion and oscillations due to marine interactions are some of the most typical loads considered on mechanical assessments. Bolted and welded joints within these structures and their connections to the surrounding structures are often subject to a battery of FEA stress analysis tests covering a range of expected load scenarios. Worst case stress and deformation are typical outcomes of these models, but natural frequencies spectrum (modal analysis) and fatigue useful life are also often required in order to prevent unanticipated failure due to oscillating loads.

Vibrations and thermal loading

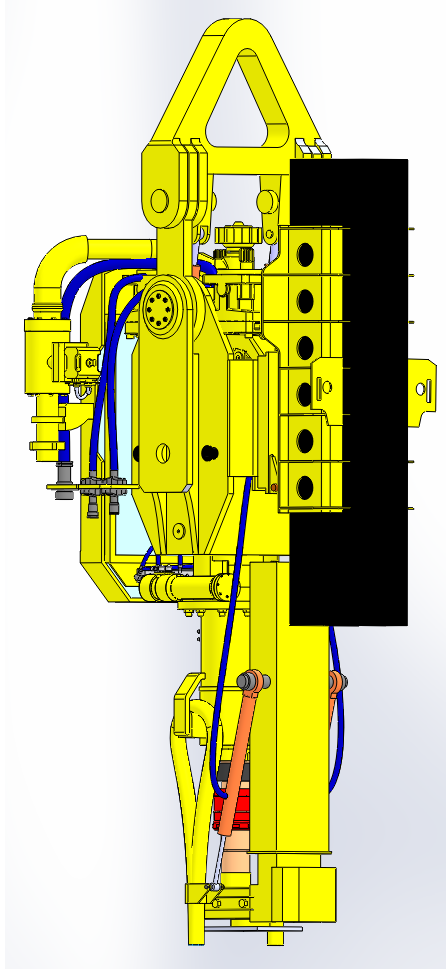

There are a number of structures especially demanding in terms of mechanical performance. Drilling structures on MODUs are a perfect example of these. Masts and derricks require thoughtful analysis often carried out using computational tools such as FEA. Derrick structures and their connections with the top drive and the rig need to be carefully assessed both for the massive forces they need to withstand but also for the continuous vibrations the structure transmits. Another demanding unit in terms of mechanical requirements is the gas compressing unit.

Compressors rotate and vibrate and even though their connections to the structure typically have dumping devices some oscillating loads are constantly transmitted to the surrounding structures. A modal analysis of the structure would help the structure designers obtain the natural frequencies of the structure. These critical frequencies are then compared to the vibration source’s frequency to assess the likelihood of resonance effects that may ultimately lead to fatigue failure.

Compressors rotate and vibrate and even though their connections to the structure typically have dumping devices some oscillating loads are constantly transmitted to the surrounding structures. A modal analysis of the structure would help the structure designers obtain the natural frequencies of the structure. These critical frequencies are then compared to the vibration source’s frequency to assess the likelihood of resonance effects that may ultimately lead to fatigue failure.

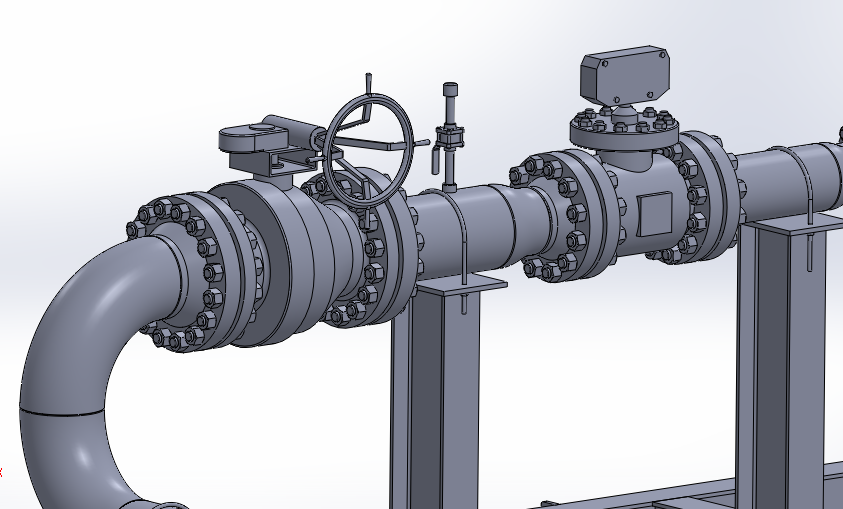

Unlike the drilling structures whose loading is purely mechanical, other rig structures also need to withstand thermal loading. Good examples of this are the flare stack and the pipeline supports. Production and processing thermal conditions constantly vary, especially on a shut-down or re-start procedure. Pipelines and their supports and fixations need to be calculated accounting for the expected thermal expansion due to these changes in temperature. A certain tolerance and flexibility is often present on pipeline supports, however stress hotspots are unavoidable. FEA based coupled thermal-mechanical models are constantly used to assess pipelines, flanges and supports.

Auxiliary structures

Depending on the location of the installation, many utilities and auxiliary systems need to be available on the offshore rig. Electricity, HVAC, compressed air and water are just some examples of systems essential to the rig operations even though they are not directly related to production or processing.

Additionally, personnel dwellings, offices for control and operations and sometimes a helipad, all need to be integrated onto the rig structure. Mechanical engineers and structure designers often struggle to accommodate all facilities over the same structure while keeping the weight balance. PRE Technologies’ engineers have assisted mechanical designers on this endeavour for the last 10 years.

Stress and fatigue calculations for frames, skids, connections and joints are the most typical examples of projects we deliver for our clients. Thermally induced stresses, plastic deformations and explosion containment are also part of PRE’s portfolio and require more complex modelling approaches.

Additionally, personnel dwellings, offices for control and operations and sometimes a helipad, all need to be integrated onto the rig structure. Mechanical engineers and structure designers often struggle to accommodate all facilities over the same structure while keeping the weight balance. PRE Technologies’ engineers have assisted mechanical designers on this endeavour for the last 10 years.

Stress and fatigue calculations for frames, skids, connections and joints are the most typical examples of projects we deliver for our clients. Thermally induced stresses, plastic deformations and explosion containment are also part of PRE’s portfolio and require more complex modelling approaches.

For more information on other services for offshore rigs and platforms, please go to the oil and gas rig tab or contact us here.

Our services for this sector

Structural integrity

- Mechanical assessment of module / skid connections and interfaces

- Skid and processing equipment sea fastening assessment

- Structural integrity of main platforms and structures

- FEA stress analysis for processing skids and pipeline supports

Vibrations

- Vibration studies for compressor units and drilling equipment

- Derrick mechanical assessment including top drive supports

- FEA modal analysis and resonance assessment for equipment and structures

- Fatigue expected useful life for equipment and structures subject to oscillating loading

Thermal loading

- Pipeline FEA stress analysis under thermal expansion loading

- Thermal shocking analysis on processing equipment

- Fatigue calculations for equipment subject to cyclical thermal loading

- Thermal expansion study on pipeline stacks and supports