Fuel cell

The customer

- Size: Small-medium company

- Sector: Fuel cell manufacturer

- Country: United Kingdom

The Project

- Size: 100-120 man-hours

- Duration: 3-4 weeks

The Problem

- Liquid water accumulation in the serpentine channels

- Thermal performance unknown in the stack

- Impact on the stack temperature of the air velocity

Proposed solution

- Model water generation and removal in the cathode

- Assess thermal performance for the full fuel cell stack

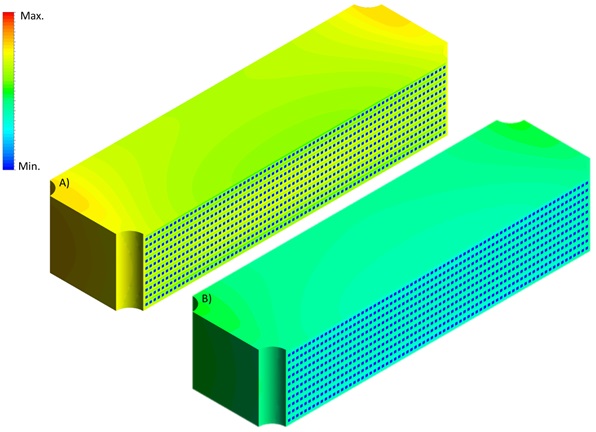

The simulations

- Multi-phase dynamic CFD simulation for the water transport (CFD analysis)

- Thermal CFD model for the fuel stack. Momentum, mass, species and energy balance was solved. (CFD analysis)

Project overall results

- Optimised serpentine geometry for minimised flooding risk. Stack thermal management assessed.

- Savings over £14,000 for the customer in prototyping and testing (estimate).

- Savings of more than 8 weeks in development time (estimate).

For more details on fuel cell simulation, please read our computational analysis for fuel cells white paper.