Spool and jumper analysis

The customer

- Size: Medium-large enterprise

- Sector: Oil and gas industry

- Country: Angola

The Project

- Size: 140-150 man-hours

- Duration: 4-5 weeks

The Problem

- Slug induced fatigue calculation

- Erosion wear estimation required

- Installation and operation mechanical loads needed assessment

Proposed solution

- Fluid flow modelling to obtain slug frequency

- Modal analysis of the structure to obtain spool natural frequencies

- Erosion modelling for various particles content

- Mechanical analysis for various installation and operational loads

The simulations

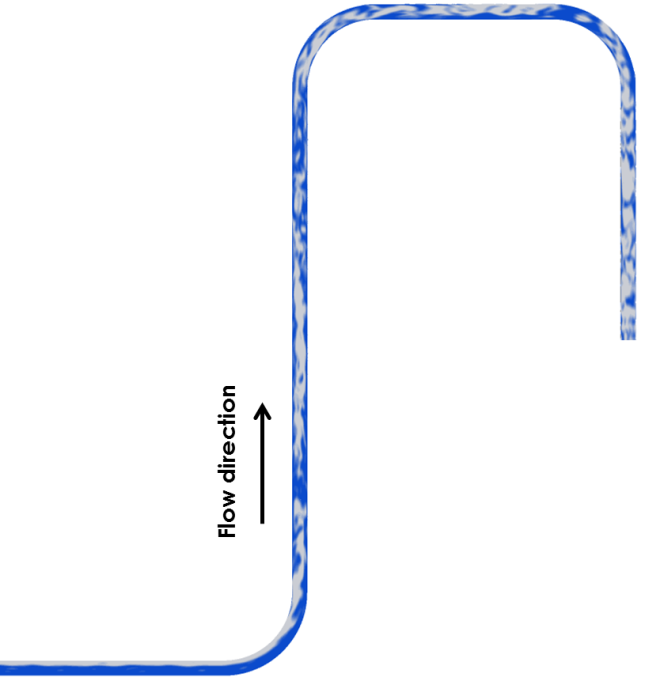

- Multiphase transient analysis to capture slugs formation (CFD analysis)

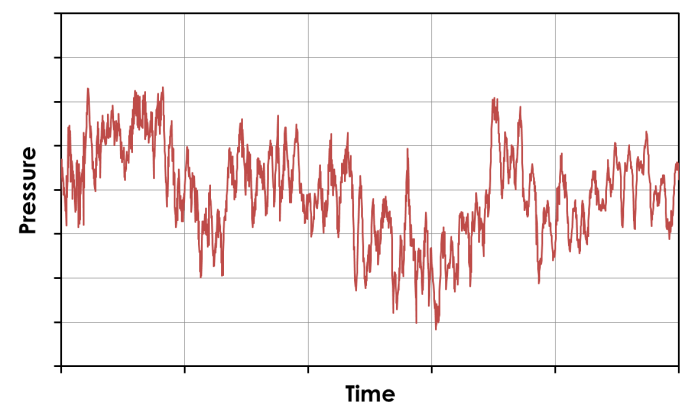

- Slugs induced pressure map on the spool. FFT to obtain the frequencies

- Modal analysis of the structure and resonance assessment (FE analysis)

- Discrete phase modelling (DPM) for erosion calculation (CFD analysis)

- Stress analysis for installation/operation loads, induction bends (FE analysis)

Project overall results

- Optimised design able to withstand all loading conditions for installation and operation.

- Savings over £18,000 for the customer in prototyping and testing (estimate).

- Savings of more than 8 weeks in development time (estimate).

For more details about spool design, please read our spool and jumper optimisation white paper.