Aeronautics - Plastics manufacturing

During the last half of the 20th century and continuing in the 21st century, aeronautical engineering has made quantum leaps, with plastics playing a major role in both pragmatic improvements and dramatic advances. From aircraft and missiles to satellites and space shuttles, plastic components and products have been essential enablers of the most significant developments in civilian air travel, military air power and space exploration.

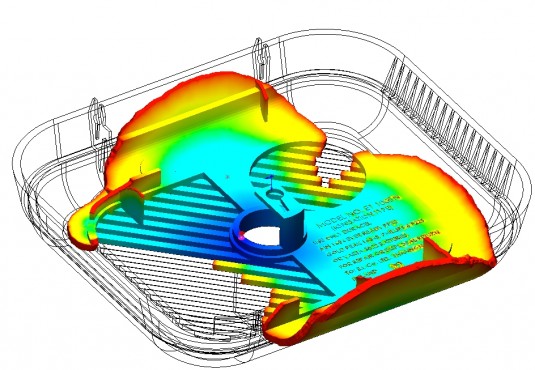

Plastic components need to be durable and strong, versatile, light-weight, aesthetically pleasant and their assembly easy and repeatable. Simulation is of paramount importance when trying to meet all these requirements. Mechanical and vibrational performance, as well as creeping analysis are just a few of the studies that PRE Technologies can perform.

Application of plastics in an aircraft ranges from the recent use in the fuselage and other structures (Boeing 787 Dreamliner) to the navigation controls or the cockpit, including interior panels, electronics, connectors and in-flight entertainment systems and comfort devices.

Aircraft sector is probably the most demanding in terms of technical requirements and safety regulations. High thermal and mechanical stability, flame resistance, low degree of thermal expansion, low level of outgassing in vacuum and high chemical resistance even at high temperatures are some of the main features plastics need to comply with.

PRE Technologies specialises in plastic components simulation which is crucial for staying in the vanguard of aircraft innovation. Mechanical and vibrational performance, as well as creeping analysis are just a few of the studies that PRE Technologies can perform.

For more information on other services for the plastic manufacturing sector, please go to the plastic manufacturing services tab.

For more information on other services for the aeronautics sector, please go to the aeronautics metal services tab.

Our services for this sector

Components design:

- Stress and vibrational studies of external structural composites

- Thermal and mechanical studies of electronic components and cases

- Rubbers deformation analysis

- Seat foam comfort and ergonomics viscoelastic study

- Mechanical performance study of rubber joints

- Lighting thermal CFD analysis

- Interior injection moulded and compression moulded parts design and analysis

- Thermo-stress viscoelastic deformations (creeping)

Components manufacture:

- Injection moulding mould filling simulation

- Compression moulding process optimisation

- Rotomoulding process cycle calculations

- Injection moulding thermal optimisation